Continuous mixers

Designed with over 30 years of industry expertise and the most reliable technology, VMI’s continuous kneading systems deliver high productivity and quality. As fully automated systems, they permit bakers to keep a constant flow of traditional kneading for raw-frozen, par-baked, and frozen doughs.

Discover our automated kneading systems and our transfer elements and ancillary systems.

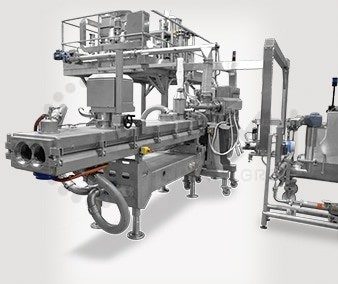

Verymix Continuous mixer

The Verymix continuous mixer is one of VMI’s major innovations. It has precise control over the kneading technique and ensures consistent quality of dough. The Verymix design streamlines the most demanding productions with its:

- Continuous weighing of the dosing units

- Independent pre-mixer (the HPM – Horizontal Pre-Mixer)

- Kneader with rotor and bowl geometry adapted to your dough

- Cooling unit that uses glycol water to adjust dough temperature

The Verymix mixer benefits from a precise yet flexible dosing system; fat in blocks or liquid, scrap dough, special flours, eggs, dried fruits, or chocolate chips can be incorporated at any time during the mixing stage.

Recipe formulation, dosing, programming, monitoring of instructions, and traceability are all managed by a user-friendly, high-performance HMI. It also allows you to measure and adjust many parameters including mixing time and intensity, dough temperature before, during, and after mixing, energy transmitted to the dough, and the opening of the glycol valves. With this HMI, you can ensure quality and consistency of dough production 24/7.

The Verymix continuous mixer is the ideal equipment for producing raw, pre-cooked, and frozen doughs such as baguettes, ciabattas, pizzas, pastries, puff pastries, and doughnuts.

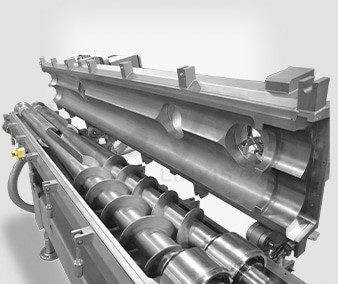

Continuum® Continuous Vacuum Mixers

The Continuum® is the first continuous vacuum mixer designed exclusively for the production of bread, bun, brioche, and other soft products.

This continuous mixer can meet the needs of mass bakery production, especially for frozen baked goods. For this, temperature control–via glycol circulation in the double jacket of the bowl–and energy control are essential. The Continuum®, like the Verymix, incorporates these features.

The two mixing phases–pre-mixing and kneading–are made possible by the presence of the HPM (a pre-mixer). Thanks to VMI’s innovative and patented tools, the HPM can quickly achieve hydration and homogenization of the mixture. And during the kneading process, the aeration and structuring of the dough are made possible by the HPM’s smaller kneading chamber, which guarantees better temperature control and energy supply. The addition of pressure or vacuum allows for modulation and better structuring of the crumb.

The Continuum® mixer’s control of all the kneading parameters allows it to achieve the best results for the end product’s softness and shelf life.