Depositing, Transfering, and Food Filling Equipment

As a specialist in mixing equipment, VMI is now also a distributor of machines made by its sister company, Unifiller Systems. Unifiller is a leading manufacturer of transferring, depositing, filling, and cake decorating equipment for the food and baking industries.

Their equipment offers a diverse range of applications, productivity, comfort, and economy to their users.

Hopper Topper Transfer Pump

The Hopper Topper transfer pump is ideal for food or bakery manufacturers looking to streamline their production process. Its unique pumping technology ensures fast and precise product transfer, regardless of product texture.

Thanks to the automatic sensor that controls the fill level of the hopper, production can run smoothly without interruption. The stainless-steel body is set on wheels, allowing for easy mobility. The Hopper Topper also has a height adjustment feature that makes it accessible for all types of tanks.

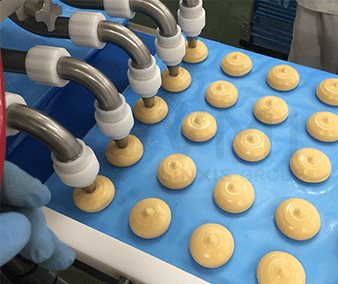

Multistation Multi-Piston Depositor

The Multistation depositor is flexible and versatile and allows food and bakery manufacturers a high production rate. Its row of pistons can deposit liquid to viscous products (creams, batters, fillings with inclusions, sauces) quickly and accurately, making it a great machine to be integrated into a production line.

Maintenance and cleaning is made easy by the quick removal of the nozzles–no tools required. Equipped with a 42-liter hopper, the Multistation can be adapted to all containers, molds, and plates up to 60 cm wide. The machine comes with a set of 6 or 8 nozzles.

Universal 1000i SV

The Universal 1000i depositor is suitable for industrial production. It can deposit batters with or without inclusions, sauces, creams, and even the most delicate mousses with speed and precision. Its deposit volume can handle deposits from 10 to 1100 ml. Over 100 accessories and attachments are available to be adapted to this machine for the applications of all bakery and food products.

The Universal 1000i is ergonomic-friendly, thanks to its lifting system that allows operators to effortlessly fill the hopper and adjust the working height. Two models are available: the standard version with foot control and a version with a hand-held nozzle.

ELF 400 SV Tabletop Food Depositor

The ELF 400 SV tabletop filling machine will be an indispensable part of your production process, enabling you to fill portions precisely, quickly, and with consistency. The machine has a 22-liter hopper with four nozzle diameters for the most diverse deposit volumes. The volume of deposits can be from 10 to 420 ml depending on the nozzle.

The ELF is made with a robust, stainless-steel structure that can be easily disassembled for quick cleaning and product changeover.

iSPOT Single Piston Depositor

Designed for operator working comfort, the iSPOT enables users to consistently pump and deposit products directly from the bowl. Produce perfectly finished desserts without worrying about downtime or food waste.

The iSPOT’s deposit volumes are easily adjustable and its body is made entirely with stainless steel. It is a versatile machine that comes with interchangeable hand-held nozzles that can transfer and deposit a wide variety of products.